Reynolds Tubing

Merlin’s dedication to the finest materials and processes starts with the right ingredients.

Why We Use Reynolds Double Butted Tubing.

In order to be one of the best titanium bicycle manufacturers in the world, it goes without saying that you have to start with the best materials. Just like with cooking, the quality of the ingredients has a tremendous effect on the results. Reynolds has more than a 100 year history making the best tubing. To quote Reynolds directly, their patented mandrel butting process allows for “…each 3-2.5 tube individually to tighter tolerances on the wall thickness compared to most of the titanium industry. This gives fabricators a very consistent tube profile and weight suitable for custom designs. The process also cold-works the material which improves the grain structure and tensile strength allowing lighter tubing to be specified.” While some other companies either butt their tubes in house or use alternate suppliers, it is Reynolds’ data backed understanding and history of developing tubing, unique butting processes and our ability to communicate directly with Reynolds that has led us to select their tubes on our frames. Each one of these frames thusly benefits from these ingredients creating an elevated ride experience that is custom tuned an uniquely Merlin.

How Do We Select Tubes?

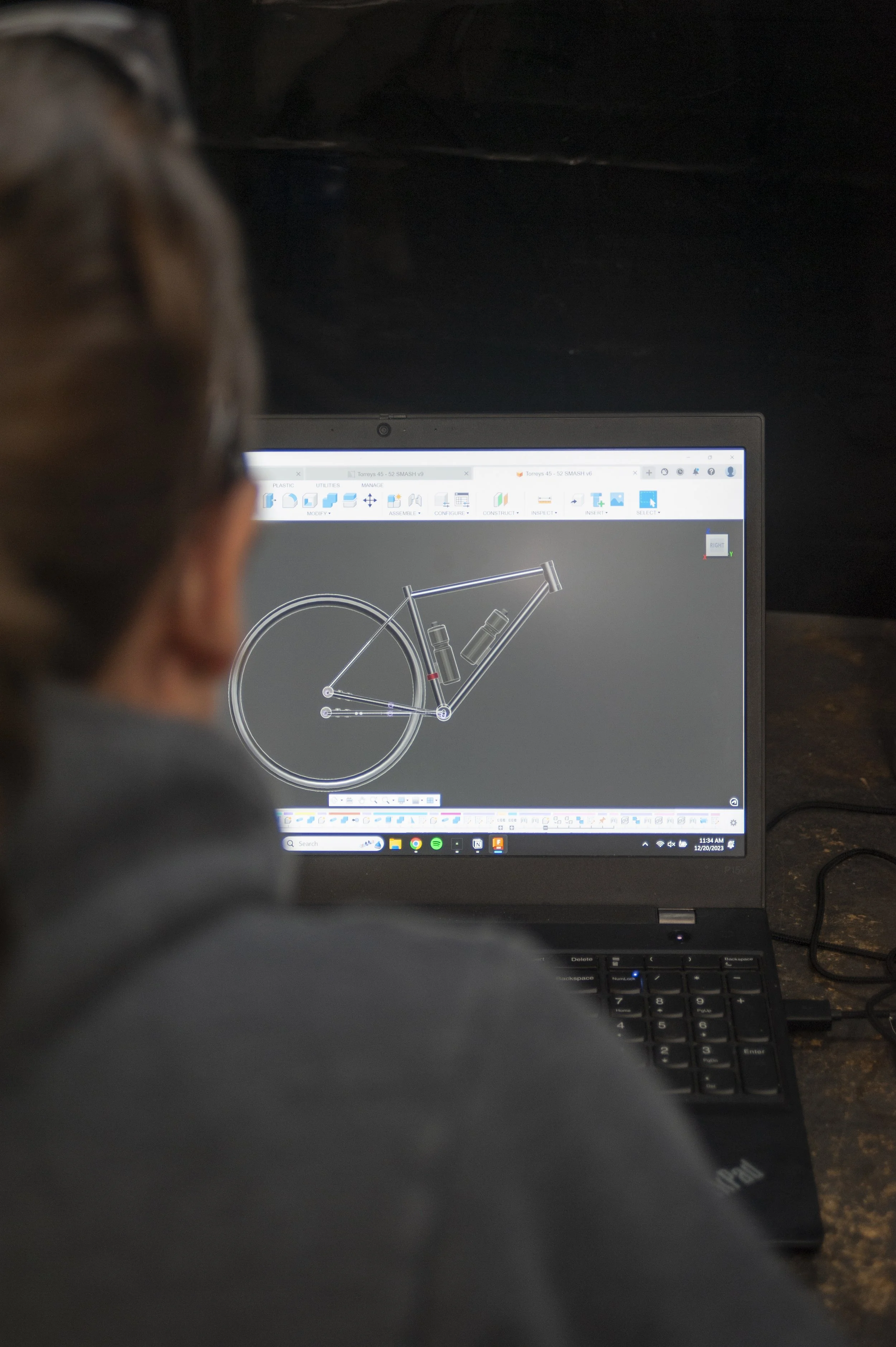

At Merlin regardless of whether your frame is a stock model or a customer fit, each customer gets a personalized tube set. With each frame, we start with the you customer. We gather the basics; height, weight and performance expectations. Once we have a picture of the customer’s needs, we create a fit model and begin selecting each tube for that specific build. It is a very one-at-a-time process. Through our deep knowledge of how these tube performs, as well as incorporating modern FEA analysis, we create a CAD model of the frame with the selected tubes to make sure all our expectations are inline. Once we have all this confirmed, we hand pick each tube, prep them and queue them up to become our customers next dream ride.

More About Reynolds Patented Process!

Did you know that Reynolds holds the original patent for double butted tubing? They have been doing butted tubes longer than anyone else. The Titanium we get from Reynolds drawing over a mandrel (DOM) press with an external die to generate the tube’s selected outer diameter (OD). The mandrel itself creates the butted profile for that selected tube. In this particular process the butted dimensions are decided by the mandrel and the OD is determined by the die. Once this process is done, to draw the mandrel out of the now butted tube, a pair of angled rollers will “reel” the tube off the mandrel. Finally the tube is then pressed through the die one more time to assure the OD is to the spec desired. At the end of the process we get a tube that is to spec, with very tight tolerances that in addition to be seamless, is also cold worked which additionally increases the strength of the tubing. Reynolds has some of the best strength to weight ratios in Double Butted Tubing. We know from experience that it is of the finest quality and the most consistent. By taking such care in the process, Merlin can repeatably make bikes that have the most customized ride quality based on the customers inputs. Stock or Custom, your Merlin will always be made with the best materials to create the best ride around. For more information on Reynolds Tubing feel free to click HERE.